IC Potash Corp.

Agapito Associates, Inc. (AAI) developed the resource, reserves, mine design, mining equipment and support systems, determined mining risks, and estimated the mining capital expenses (CAPEX) and operating expenses (OPEX) for a Feasibility Study (FS) for IC Potash Corp. (ICP)’s Ochoa Polyhalite Mine Project, located in southeastern New Mexico. SNC-Lavalin Inc. (SNCL) was the lead consultant for the FS and developed the processing and facility infrastructure, project scheduling, and overall cash flow modeling portions of the FS. AAI was the lead consultant developing the FS-based National Instrument (NI) 43-101 Technical Report scheduled to be posted on the System for Electronic Document Analysis and Retrieval (SEDAR) website by March 7, 2014.

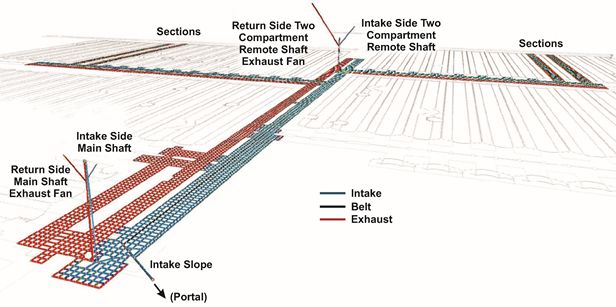

The Ochoa Mine Project will be the first fully commercial polyhalite mine and processing facility to be developed. The polyhalite ore body averages over 1,500 feet (ft) deep and will be accessed by a 25-ft-diameter two-compartment ventilation shaft, equipped with an emergency escape hoist, and a 12,000-ft-long, 15% mine slope (decline) for a 60-inch-wide, 10,000-horsepower (hp) belt conveyor ore haulage system, personnel travelway, equipment and supply travelway, and intake air. The mine is projected to produce an average of 3.7 million tons per year of run-of-mine (ROM) polyhalite ore, averaging 78.05% polyhalite. Mining height averages over 5 ft. The mine is expected to employ 250 people at full production. Total employment for the mine and plant is expected to be 400 people. A total of seven heavy-duty drum-type continuous miners will be used for ore production. Mine ventilation will be supplied by two 11-ft-diameter vane axial powered by 1,500-hp motors. The mine substation is designed as a 30/40-megawatt facility, with the mine’s underground electrical distribution system at 12,470 volts.

AAI reviewed and audited the exploration drilling and assay program, developed independent geologic models to calculate Mineral Resources, conducted empirical and 3D numerical modeling mine geotechnical analysis for mine design, oversaw linear cutting tests, and developed productivity simulations used for mine production scheduling, and estimating power, ore haulage systems, and ventilation requirements. From the resource model and mine projections, AAI estimated the Mineral Reserves for a 50-year mine plan. In addition, AAI developed the mine access designs and contractor bid packages for the mine shaft and slope. From these analyses, mine capital and operating costs were calculated and provided to SNCL for cash flow economics.

It is estimated that the project will produce over 700,000 tons per year of Sulfate of Potash (SOP), in a combination of standard, granular, and soluble SOP.