ConocoPhillips Company retained Agapito Associates, Inc. (AAI) to develop a conceptual mine plan for a modified in-situ (MIS) oil shale mine located in Rio Blanco County, Colorado.

The scope of work for this project was to review concepts for MIS recovery of shale oil and to develop a preliminary mine plan that allows demonstration of the MIS concept after development of the conventional room-and-pillar operation. Subtasks included:

- Review of concepts from ConocoPhillips and existing MIS mine plans

- Development of MIS basis for design to identify constraints and functional requirements for components (drifts, pillars, void, rubblization, ventilation, etc.) and safety

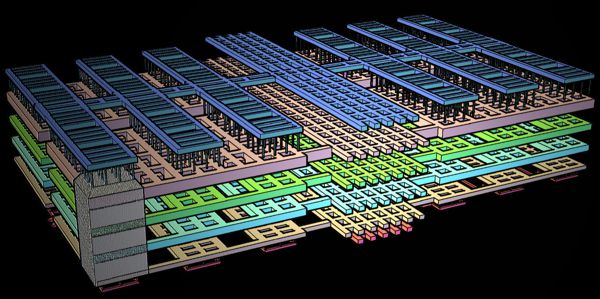

- Concept development for basic MIS retorts and integration of retorts with room-and-pillar mine plan

- Development of concept drawings

- Development of retort development costs from concept drawings, equipment list, and man-power estimates

The mine development plan was based on practices at nearby oil shale mines such as the Colony Mine now owned by ExxonMobil and the Unocal oil shale mine, modified for experience and technological improvements. Conceptual retort designs (retort void development) were based on the experience and experimental demonstration of concept developed by Occidental Petroleum (Oxy) at their Logan Wash facility in the 1970s, commercial mine plans developed for the C-b Tract through early 1981, and the Proof of Concept mine plan for C-b Tract developed by Oxy in 1990. AAI personnel were involved as consultants for all the Oxy MIS projects. The team who has developed this plan included independent consultants who were former Oxy employees and had direct experience in the design and operation of the full-scale retorts at Logan Wash.

The mine development plan was based on practices at nearby oil shale mines such as the Colony Mine now owned by ExxonMobil and the Unocal oil shale mine, modified for experience and technological improvements. Conceptual retort designs (retort void development) were based on the experience and experimental demonstration of concept developed by Occidental Petroleum (Oxy) at their Logan Wash facility in the 1970s, commercial mine plans developed for the C-b Tract through early 1981, and the Proof of Concept mine plan for C-b Tract developed by Oxy in 1990. AAI personnel were involved as consultants for all the Oxy MIS projects. The team who has developed this plan included independent consultants who were former Oxy employees and had direct experience in the design and operation of the full-scale retorts at Logan Wash.

This report contains a description of the resulting MIS conceptual plan and the estimated operating and capital costs for the underground portions of the project. Mine capital and operating costs are estimates or allowances based on a combination of previous studies, vendor estimates, and published cost guides. Capital costs include mine access, mining equipment, inter-level access ramps, and production to injection level shafts (one per two panels) for retort produced gases.