Feasibility Study Solution Mining

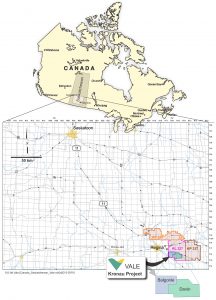

AAI completed an FEL-3 Feasibility Study in conjunction with WorleyParsons Ltd. and Vale for the Kronau Project, a 4-Mtpy MOP conventional cavern solution mine on potash lease KL 227 southwest of Regina, Saskatchewan. AAI was responsible for the solution mine plan including cavern creep modeling, cavern design and pillar sizing, production well design, optimizing cavern yield and wellfield layout, and estimating transient subsidence during mining and ultimate subsidence post-mining. AAI developed the wellfield schedule and capital and operating costs for the solution mine. AAI prepared the maiden NI 43-101 Technical Report (TR) documenting the Feasibility Study and stating Mineral Resources and Mineral Reserves.

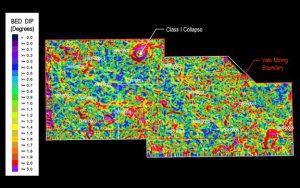

Earlier, AAI completed an FEL-2 Prefeasibility Study for the project. AAI estimated Mineral Resources for both the FEL-2 and FEL-3 studies. The FEL-3 resource estimate was updated on the basis of results from a multi-year exploration drilling program, detailed 3D seismic survey data, QA/QC analysis, and multi-bed geostatistical modeling using MineSight® software.

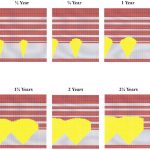

Detailed wellfield forecasting was conducted for the FEL-3 Feasibility Study using Solution Mining Cavern Design (SMCD) 2.0, a proprietary code developed by AAI for solution mine design. SMCD was used to position and orient the caverns for optimum recovery and to quantify recoverable tonnages for each cavern based on the local bed dip, bed thickness, grade, orientation of the cavern (azimuth) relative to dip, and interburden thickness limits. Solution Mining Production Scheduling (SMPS) 1.0, another proprietary computer code developed by AAI, was used to simulate the cavern mining sequence and brine production quality continuously over the life-of-mine based on the cavern-by-cavern yield computed by SMCD.