West Elk Mine—Somerset, CO

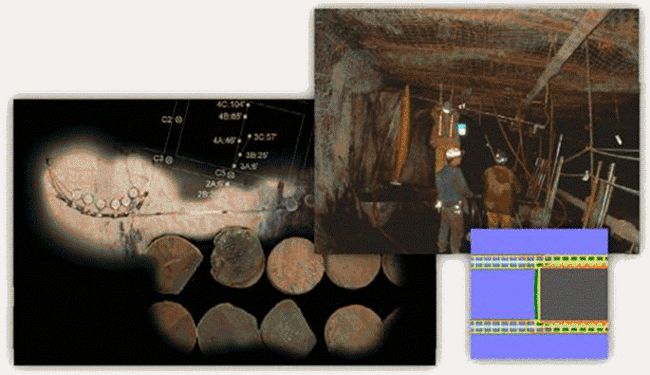

AAI has provided underground geotechnical engineering services to Mountain Coal Company’s West Elk Mine since the 1980s. Services include installation of geotechnical instrumentation, in-situ stress measurements, laboratory rock properties testing, periodic ground control reviews, pillar and barrier sizing analysis, shield size specification, geotechnical characterization for shaft design, subsidence evaluation, and geological support for exploration drilling.

Mountain Coal commissioned AAI to collect baseline geotechnical data to support gateroad and bleeder design for future longwall mining under deep cover in the B Seam. Twenty-four encapsulated borehole pressure cells were installed in ten pillars and one barrier at four separate headgate and tailgate sites. Nearby intersection roofs were instrumented with two-point sagmeters. AAI procured, drilled, installed, and tested all instruments. Instruments were monitored during the passage of two longwall faces, providing detailed histories of roof movement, pillar loading, and abutment load transfer. Overcoring was conducted to measure the in-situ stresses. AAI also cored and tested samples in the roof, coal seam, and floor to characterize the unconfined compressive strength and elastic modulus of the host strata.

Data from the instrumentation, overcoring, and testing program supported numerical analysis of competing gateroad design options conducted by AAI.

In 2010, AAI instrumented two sites with BPCs and closure stations to monitor gateroad performance during retreat of the first and second panels in the E Seam. Data were used to calibrate numerical models and refine gateroad and barrier design for later E Seam panels.